INDUCTION HEATING MACHINE

Malhotra Technologies is a Bahadurgarh (Haryana) based Industrial Equipment Manufacturer and seller of solid Induction heating Machines.

Induction heating machines use electromagnetic fields to heat materials efficiently and perfectly. A specialized induction heating machine for a start-up line is designed to improve production processes by offering quick setup times, precise temperature control, and ease of use. Induction heating machines are essential for Industrial Operations.

Features of Induction Heating Machine

TYPE OF

INDUCTION HEATING MACHINE

Induction Heating Machine Application

The Induction Heating Machine Proposal has many Advantages over traditional heating methods, making it extremely required in Industries such as metalworking, aerospace, medical, automotive, and manufacturing. The key benefits of the Induction Heating Machine include:

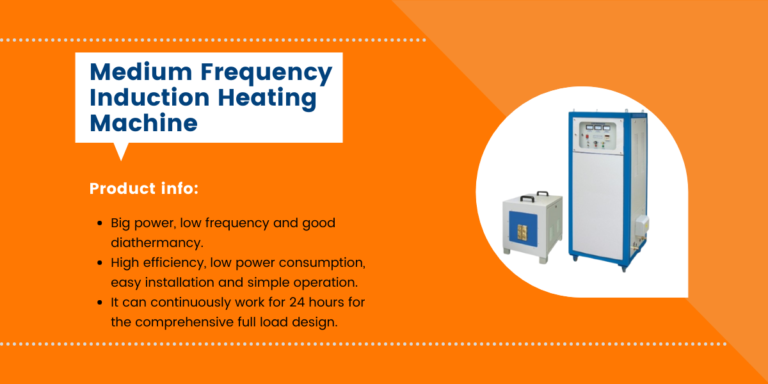

Induction Heating Machines are used in Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting, and red stamping. These processes all used induction heating machines to make the workpieces have nearly the same temperature on the surface and internally.

Brazing is a heat Treatment method with an Induction Heating Machine. Induction Heating Means producing the alternating magnetic field through an Induction Coil after Induction Heating Equipment outputs a High-Frequency current to heat the workpiece quickly.

The Heat treatment process is when the metal workpiece is heated to a certain temperature, and obtains different matrix organization after different ways of cooling, so as to achieve the required mechanical properties(material harder or softer), such as quenching, annealing, etc.

Super audio frequency induction heating machine

A Super-audio frequency Induction Heating Machine utilizes a high-frequency electromagnetic field to generate heat within conductive materials. Most likely, the MTC-30kw available is at the lowest price.

Usage:

Hot Forging, Quenching, Stainless Steel Annealing.

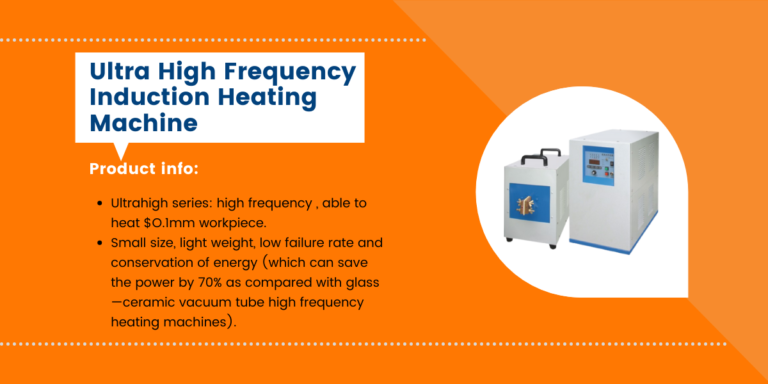

UHF induction heating machine

An ultra-high frequency induction heating machine is a specialized heating device that has an ultra-high series: high frequency, able to heat 0.1 mm workpieces. It has

a small size, light weight, low failure rate, and conservation of energy(which can save power by 70% as compared with glass-ceramic vacuum tube high-frequency heating machines).

Recommend Usage:

Brazing, heat treatment, forging, etc.

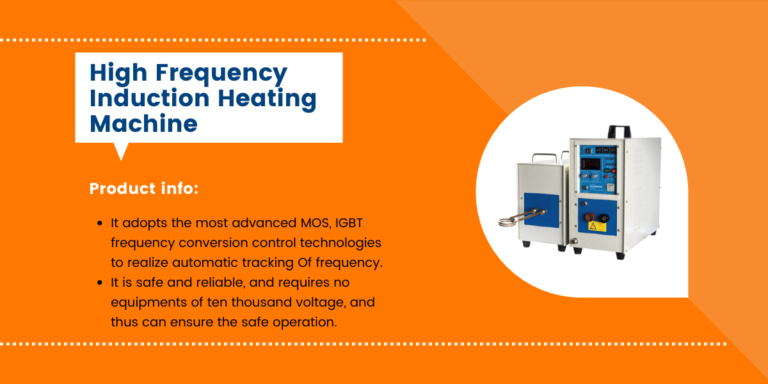

High-frequency induction heating machine

A Heating Machine, called a High frequency induction heating machine, heats electrically conductive materials by using electromagnetic fields. An induction coil generates a magnetic field when a High-frequency alternating current flows through it, and then the material heats up.

Usage:

Brazing, Forging, hot Banding, Melting, and Annealing for Stainless Steel Goods.

Who Are We?

Why choose an induction heating machine?

Induction Heating machines use large hardening workpieces, tempering, cooling, solid design, and high-frequency induction heating machines that are fully automatic. 3kw to 300kw series of Induction Heating Machine.

Induction Heating Machine

Requirement

India Mart

Requirement

India Mart

What Our Customers Say About Us

Why Choose Us

When It Comes to Reliability, We Are the One You Need!

Request Callback

Please Complete the Form

We are here to help you! Call Us Today!

Add: GR36A/2, Ganpati Dham Industrial Area, Bahadurgarh – 124507 (Haryana)

What is an Induction Heating Machine?

Induction Heating Means to produce the alternating magnetic field through an induction coil after induction heating equipment outputs high-frequency current to heat the work pieces quickly and safely.

Usage:

> Thermoforming (Hot-Forging, Heat Penetration Formation, Hot Rolling

> Brazing (Brazing, hot Cooperation, Hot Painting)

> Melting (Gold Melting, Silver and Gold, S.S., other Metal Material)

> Hardening (heat Treatment, Quenching, Shafts, Annealing)

Why Induction Heating is Important in Modern Manufacturing, and how it is Superior to Traditional Methods ?

In Today’s Modest Manufacturing Environment, The Induction Heating Process needs to be Fast, environmentally Friendly, and Precise — and this is Why the Induction Heating Machine has Beaten all Traditional techniques. High Frequency Induction Heating Machine and Ultra High Frequency Induction Heating Machine, Developed by Malhotra Technologies, are Redefining Manufacturing in India with care and energy-saving Heating. Induction Heating Machine in Bahadurgarh (Haryana) near Delhi. Malhotra Technologies.

Induction Heating Machine Price in Delhi?

An Industrial induction heating machine price can range from around rupees 1.25 lakh to 6.75 lakh. dependent on the machine’s power and capacity. For the best industries required induction heating machines, prices start from 1,25,000 rupees 10kw machines. high frequency induction heating machine may cost 4 lakhs for a more heavy-duty industrial application. Choose for right induction heater (induction heating machine)

Air Cooling Induction Heating Equipment?

An Air cooling induction machine is a specialized system used for heating metal components without requiring a water-based cooling system. The main power component of this product uses the cool wind condition to proceed cooling, which can enhance the energy transformation and reduce the electrical energy loss which cuts the equipment’s failure rate effectively and guarantees the useful life of the equipment. It mainly applies in the low temperature condition, heating about 0-500 c. For example:

An Air cooling induction machine is a specialized system used for heating metal components without requiring a water-based cooling system. The main power component of this product uses the cool wind condition to proceed cooling, which can enhance the energy transformation and reduce the electrical energy loss which cuts the equipment’s failure rate effectively and guarantees the useful life of the equipment. It mainly applies in the low temperature condition, heating about 0-500 c. For example:Food roasting, zinc-base alloy melting.