HIGH-FREQUENCY INDUCTION HEATING MACHINE

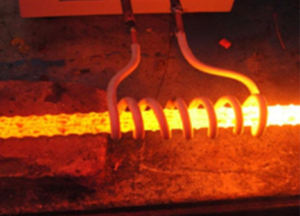

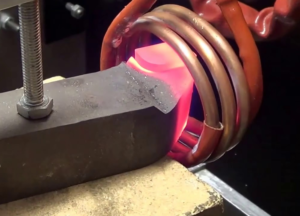

A Machine called a high frequency induction heating machine heats electrically conductive materials by using electromagnetic fields. An induction coil generates a magnetic field when a high-frequency alternating current flows throgh it, which causes heating because of the electrical resistance created by the eddy currents this field creates, the material heats up.

Main Feature of High-Frequency Induction Heating Machines

1. It adopts the most advanced MOS, IGBT frequency conversion control technologies to realize automatic tracking of frequency.

2. It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

3. About ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

4. It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

5. It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

High Frequency Induction Heating Machine

The price of high-frequency induction heating machine in India range depending on the machine’s power capacity, frequency range, and application needs. Typically, these machines range up to ₹1.25 lakh to over ₹30 lakh. GET PRICE DETAILS.

– Heating for the copper or steel plate

– Rotor hot cooperation

– Annealing for steel products

– Hot forging for watchcase

– Heating for cartridge case

– Radiator hot cooperate

– Brazing switched to a contract

– Brazing for aluminum for sealing

– Brazing for cutting tools

Here are the key Technical Parameters of a high-frequency induction heating machine in simple terms:

>1.Power Output : The machine’s power capacity, usually measured in kilowatts (MT-5kw To MT-120kw ) , Determines how quickly and intensely it can heat metal,

2.Frequency Range : High-frequency machines operate between 100 KHz to 1 MHz. Higher frequencies are ideal for heating small or thin parts quickly.

3. Voltage : Input voltage is typically in the range of 220V to 480V, Depending on the machine can heat the metal, and it caries depending on the material and power settings.

4. Heating Speed : This describes how fast the machine can heat the metal, and it varies depending on the material and power settings.

5. Temperature Control: The machine allows percise control of the temperature, often ranging from a few hundred to over 1500’c, Depending on the application.

6. Cooling System : A built-in water colling system is essential to prevent overheating of the induction coils and amahcine components during operation.

7. Size of workpiece : This depends on the coil and power, higher-power machines can heat larger or thicker workpieces.

- It adopts the most advanced MOS, IGBT frequency conversion control technologies to realize automatic tracking Of frequency.

- It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

- About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide higher reliability and durability.

- It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

- It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

Applications

Heating cartridge cases is a valuable technique for fill up, as per makes change size and divesting easier and helps foil damage to the brass. This process like using a furnace, propane torch, or hot water bath are effective, with the furnace method being the most common for equally heating multiple cases. It’s important to monitor the temperature carefully to dodge weakening the brass. Overall, heating cartridge cases is a simple yet central step for make sure smooth and safe reloading.

1. Heat treatment make the metal softer and relaxed to shape or form.

2. It checks the metal from attractive too breakable, reducing the risk of cracks during processing.

3. Heated metal is easier to cut, bend, or weld, making construction more efficents.

4. Heating relieves Internal Stresses with in the metal, preventing warping or distortion during use Proper Heating can improve the strength and longevity of the metal.

1. Brazing form a strong, heavy-duty bond between the tool body (a lot made of steel) and the hurtful end (usually tungsten carbide or other hard metals). Make sure the cutting edge stays inflexibly attached during heavy-duty use.

2. Brazing arrange for a high level of accuracy when attaching the cutting edge to the tool body, make sure proper alignment and tool balance for prime performance.

3. Brazing heat treatment agrees the use of different materials for the cutting edge and tool body, merging cost-efficient steel with wear-resistant carbide. This cuts the overall cost of tools while making improvements.

4. It used also a variety of cutting tools, such as saw blades, milling cutters, and Facing Machines, where a strong, wear-resistant edge is attracted.

High-frequency induction heating machine for forging

Overview

Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-pieces nearly have the same, temperature on surface and internal, then punching into required shape, which mainly adopt electromagnetic induction and heat conduction principal.

What We Do

Malhotra Technologies was founded in 2006, which is engaged in R&D, production and sale of solid Induction Heating Machine professionally. Several senior experts of Induction Heating equipment gathered here, who initiate the Induction Heating Machines with environmental protection and highly effective energy conservation, positively and diligently.

Now there are series of products range from 3kw to 300kw, including the ultra-high/ super-audio/ medium frequency induction heater, IGBT energy saving IF power supply and special equipments(e.g. High-Frequency quenching machine, Medium-frequency induction melting furnaces, superaudio-frequency annealing machine, Induction forging furnace, brazing machine, branch distributor/ bicycle fittings special – purpose welding machine, Railway river furnaces, etc). These product are widely applied in the heating of hardware, metal(steel, iron, copper, aluminum) processing, plastic, deeply heating shaping, brazing, hardening, melting, annealing, hot cooperation and so on.

Inner gear quenching, 420 tube quenching, u-shape lock quenching, annealing of stainless steel pot,

Brazing kettle, Brazing Iron, Brazing speaker mesh, Brazing for contact, Steel needle brazing, Steel and copper Brazing,

The Vertical Solid High Frequency Quenching Machine

The Vertical solid high-frequency quenching machine is one of the complete set induction heating equipment of our companies. It mainly applied processing axis class and the gear components, but also the plate class components and the peculiar part. It adjust the high/ medium/ ultrasonic frequency power source, using the spray coolant conditions, can meet factories normal request. For the hydraulic pressure actuation, the electrical control semiautomatic machine, mainly used in quenching, annealing or the fire working procedure, it has manually, semi-automatic, and full-automatic function, simple operation and easily to learn.

HIGH-FREQUENCY INDUCTION HEATING MACHINE (MTC-30KW)

A High frequency induction heating machine series 30kw power is an advanced equipment used for efficiency and fast heating of metal parts. These machine

Max. Output Power = 30kw

frequency power = 30 – 100

Water Cooling Pressure

1 Transformer

Input Voltage = 3 phase 380V 50/60Hz

industries for applications like forging, Annealing Furnace, brazing, soldering, and heat treatment With precision control and energy efficiency, they offer a clean, non-contact method of heating. Many manufacturers focus on providing durable, easy-to-operate models that cater to various industrial needs, insure that high performance and reliability. It has 30kw machines price just 3lakh rupees.

– big power

– low frequency and good diathermancy

– high efficiency

– low power consumption

– easy installation and simple operation

It can continuously work for 24 hours for the comprehensive full load design.

recommend usage: forging, melting, quenching, etc.

10kw – 1.25lakh

15kw – 1.5lakh

25kw – 2.5lakh

30kw – 3lakh

Malhotra technologies is a reputed company that manufacture and supplies a broad assorment of induction heating machine.

Company-Related Frequently Asked Questions

We are the manufacturer and we have more than 15 years experience in laser cutting & engraving equipment. Our service after sales is good, we know how to solve the problems encountered in the use of the machine.