HIGH-FREQUENCY INDUCTION HEATING MACHINE

MANY TYPE OF INDUCTION HEATING MACHINE

> MEDIUM FREQUENCY INDUCTION HEATING MACHINE

> ULTRA HIGH-FREQUENCY INDUCTION HEATING MACHINE

> SUPER-AUDIO FREQUENCY INDUCTION HEATING MACHINE

Main Feature of High-Frequency Induction Heating Machines

2. It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

3. About ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

4. It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

5. It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

What We Do

We are more than just an Induction Heating Machine Provider.

Malhotra Technologies Established in 2007, Malhotra Technologies is a reputed company that manufactures and supplies a broad assortment of induction-hardening machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machines, sintering machines, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15-series induction heaters, 25-series induction heaters, 35-series induction heaters, 70-series induction heaters, medium frequency power heaters, melting machine frequency power heaters, and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms. Under the supervision of the company’s mentor, Mr. Naveen Malhotra, they have been successful in supplying the best products. Backed by vast industrial knowledge, he motivates everyone working for the company to bring out their best.

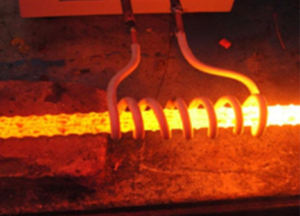

High Frequency Induction Heating Machine

The price of high-frequency induction heating machine in India range depending on the machine’s power capacity, frequency range, and application needs. Typically, these machines range up to ₹1.25 lakh to over ₹10 lakh. GET PRICE DETAILS.

– Heating for the copper or steel plate

– Rotor hot cooperation

– Annealing for steel products

– Hot forging for watchcase

– Heating for cartridge case

– Radiator hot cooperate

– Brazing switched to a contract

– Brazing for aluminum for sealing

– Brazing for cutting tools

Here are the key Technical Parameters of a high-frequency induction heating machine in simple terms:

>1.Power Output : The machine’s power capacity, usually measured in kilowatts (MT-5kw To MT-120kw ) , Determines how quickly and intensely it can heat metal,

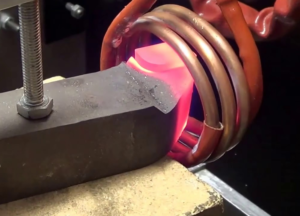

2.Frequency Range : High-frequency machines operate between 100 KHz to 1 MHz. Higher frequencies are ideal for heating small or thin parts quickly.

3. Voltage : Input voltage is typically in the range of 220V to 480V, Depending on the machine can heat the metal, and it caries depending on the material and power settings.

4. Heating Speed : This describes how fast the machine can heat the metal, and it varies depending on the material and power settings.

5. Temperature Control: The machine allows percise control of the temperature, often ranging from a few hundred to over 1500’c, Depending on the application.

6. Cooling System : A built-in water colling system is essential to prevent overheating of the induction coils and amahcine components during operation.

7. Size of workpiece : This depends on the coil and power, higher-power machines can heat larger or thicker workpieces.

- It adopts the most advanced MOS, IGBT frequency conversion control technologies to realize automatic tracking Of frequency.

- It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

- About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide higher reliability and durability.

- It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

- It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

Applications

Prevent Cracking: Annealing softens the brass, preventing cracks or splits during future use, especially after repeated firing and resizing.

Extend case Life: Regular Heating allows the brass to be reused multiple times. prolonging the lifespan of cartridge cases.

Enhances Case Life: Regular Heating allows the brass to be reused multiple times, prolonging the lifespan of cartridge cases.

Increase Safety: proper heating prevents case failure during firing, making it safer.

Easier Reloading: Softer brass is easier to resize and reload.

Reduces Stress: Heating relieves stress in the metal, Reducing the chance of wear and tear.

1. Heating makes the metal softer and easier to shape or form.

2. It prevents the metal from becoming too brittle, reducing the risk of cracks during processing.

3. Heated metal is easier to cut, bend, or weld, making construction more efficents.

4. Heating relieves Internal Stresses with in the metal, preventing warping or distortion during use Proper Heating can improve the strength and longevity of the metal.

2. Brazed joints can withstand high temperatures generated during cutting operations, making them ideal for high speed cutting tools

3. Brazing provides a high level of precision when attaching the cutting edge to the tool body, ensuring proper alignment and tool balance for optimal performance.

4. Brazing allows the use of different materials for the cutting edge and tool body, comboining cost-efficient steel with wear-resistant carbide. This reduces the overall cost of tools while making improvements.

5. It can be used for a variety of cutting tools, such as saw blades, drill bits, milling cutters, and Facing Machines, where a strong, wear-resistant edge is required.

High-frequency induction heating machine for forging

Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-pieces nearly have the same, temperature on surface and internal, then punching into required shape, which mainly adopt electromagnetic induction and heat conduction principal.

HIGH-FREQUENCY INDUCTION HEATING MACHINE (MTC-30KW)

A high-frequency induction heating machine with 30kw power is an advanced equipment used for efficient and fast heating of metal parts. These machines are widely used in industries such as automotive, aerospace, and manufacturing for applications like forging, soldering, and heat treatment With precision control and energy efficiency, they offer a clean, non-contact method of heating. Many manufacturers focus on providing durable, easy-to-operate models that cater to various industrial needs, insure that high performance and reliability.

Company-Related Frequently Asked Questions

We are the manufacturer and we have more than 15 years experience in laser cutting & engraving equipment. Our service after sales is good, we know how to solve the problems encountered in the use of the machine.