Induction heating machine for forging choice for best job

Copper wire annealing take in heating copper wire to a specific temperature and then cooling the situation in professionally.

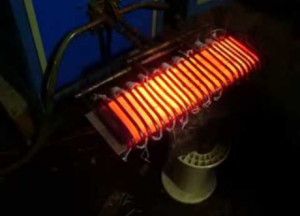

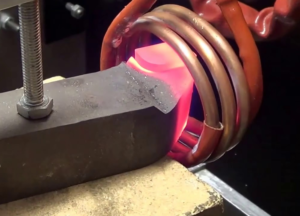

hot forming , hot forging, and red stamping are all used induction heating machine to make the work-piece nearly have the same temperature on surface and internal, then punching into required shape, which mainly adopt electromagnetic induction and heat conduction principal.

Induction Brazing Machine

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of solder, or the temperature of metal material to reach between nonmetallic materials. Its main features: good working conditions, high efficiency, good tightness and performance after brazing, simple operation and high safety, no pollution, and high fire resistance.

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machine, Induction Forging Machine, high-frequency induction heater, medium-frequency power heater, UHF induction heater, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and Induction brazing machine. They also supply products like 15 kw series induction heaters, 25 kw series induction heaters, 35 kw series induction heaters, 70 kw series induction heaters, medium frequency power heaters, melting machine frequency power heaters, and forging furnace frequency power heaters. These items are developed using high-quality raw materials secured from retailers following international model. Special Purpose KNOW MORE 25 years professional manufacturing