INDUCION HEATING MACHINE

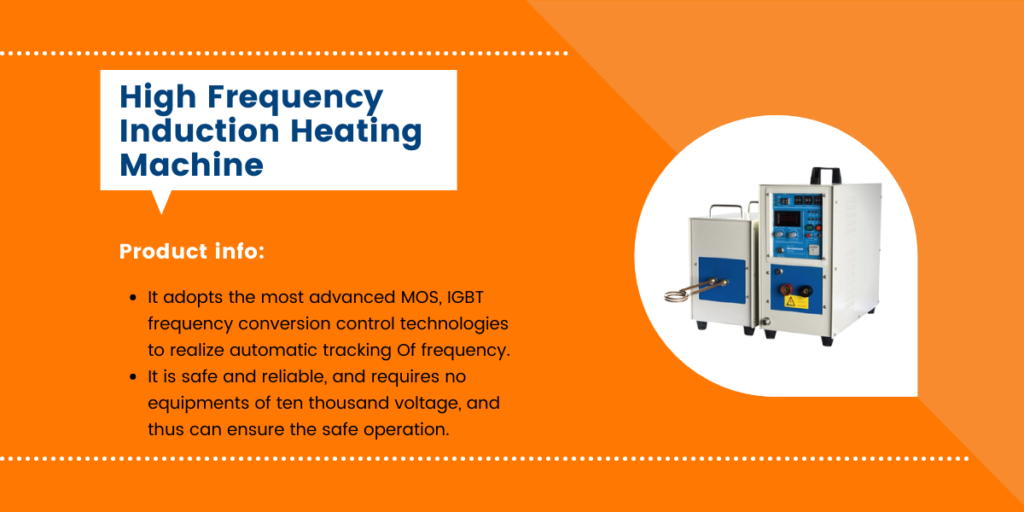

A High Frequency Induction Heating Machine mtc-30kw Is a Multipurpose and Powerful Equipment Designed for A Manufacturer Industrial Application. High Frequency Induction Heating Machine mtc-30kw Is Adopting the Most Advanced MOS, IGBT Frequency Conversion Control Technologies to realize automatic tracking of frequency. Induction Heating means to produce the alternating magnetic field through induction coil after induction heating equipment outputs high-frequency current to make the work piece heated quickly. High frequency induction heating machine recommend usage for hot forging, quenching, stainless steel annealing.

Main Features :

– It has the continuous current and power control function. Which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

– About ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

– It is secured and reliable, and requires no eqipments of ten thousand voltage, and thus can ensure the sale operation.

– It is available for infrared temperature measurement, which can realize the automatic control of temperature improve the heating performance and simplify the manual operation.

The high-frequency induction heating machine MTC-30kW is a robust, efficient, and highly precise tool that meets the needs of various industrial applications. With its energy-efficient design and fast heating capabilities, it improves production times and enhances the quality of metalworking processes As people like hihg frequency Induction Heating Machine.

Induction Heating Machine mtc-30kw

high frequency series price

The price of high-frequency induction heating machine in India range depending on the machine’s power capacity, frequency range, and application needs. Typically, these machines range up to ₹1 lakh to over ₹10 lakh.More Details

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms. KNOW MORE