A Medium frequency induction heating machines is a specialized device used for heating materials, typically metal, through electromagnetic induction. This method relies on generating an alternating magnetic field around the material to produce eddy current, which in turn generate heat due to the electrical resistance of the material.

Power Supply

Converts standard electrical power (AC) to the required medium frequency current (typically between 1KHZ to 100 KHZ

Inductor Coil

The work coil where the material (workpiece) to be heated is placed. The alternating current in the coil creates a magnetic field in the workpiece

Water cooling system

Cooling system to cool the machine components , especially the induction coil, since induction heating generates significant heat

Control Unit

Control Unit allows for adjusting parameters like frequency, power level, and heating time, ensuring precise control of the heating process.

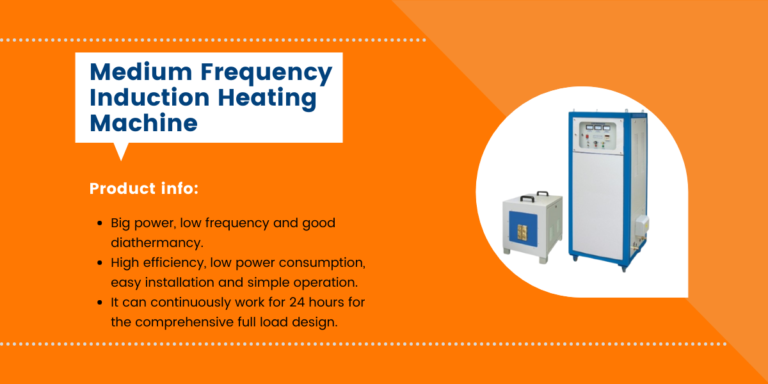

- Big power, low frequency and good diathermancy.

- High efficiency, low power consumption, easy installation and simple operation.

- It can continuously work for 24 hours for the comprehensive full load design.

- It adopts the IGBT inverter circuit in parallel connection, which has high load adaptability.

- It has functions as over-voltage, over—current, over—heat, phase loss and water shortage alarm indications as automatic control and protection.

- Compared with other heating modes, it can significantly promote the economic benefits, improve the quality of heated work pieces, save the energy and material, alleviate labor intensity and improve the production environment.

– Medium frequency forging

– Heating for iron bar

– Aluminium Melting

– Powder Metallurgy sintering

– Medium frequency melting furnace

– Heating for medium frequency

– Melting

– Heating steel products

– Bar end heating for the pneumatic feeding

– Bar end heating for the manual feeding

Why choose us Induction Heating machine

Fast heating, Widely Applicable, Low Power Consumption, High Effectiveness, High Efficiency, Small Size and light weight, Easy Operation, Environment Protection.

Applications Examples

-Medium Frequency induction heating machine are Ideal

Medium frequency heating is used in various industrial applications where there is a need for fast, efficient and controlled heating of metals. The Aavrtti range (10 kilohertz to 500 kilohertz at Aamataur) is made broad, which allows for heating of a part that is either of medium size or without much heating at the same time.(Read More Induction Heating Machine)

Medium frequency melting is a process commonly used in foundries and metalworking industries to melt metals using medium-frequency induction furnaces. These furnaces operate at frequencies typically ranging between 150 Hz and 10 Khz. The Process involves electromagnetic induction to heat and melt metals efficiently.(Induction Heating Machine by Malhtora technologies)

Model Selections

recommend Usage:

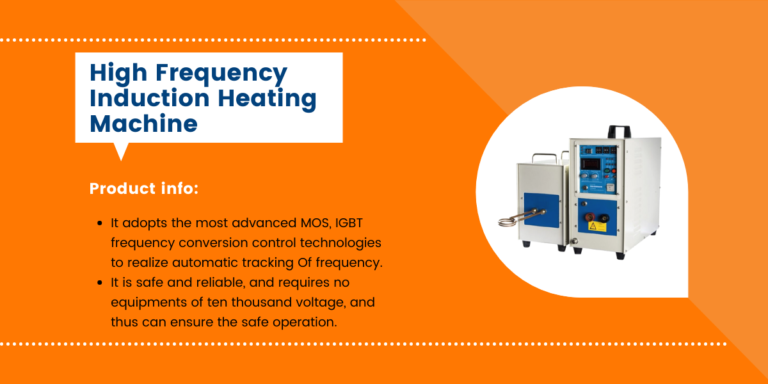

Hot Forging, Quenching, Stainless Steel Annealing.

Recommend Usage: Brazing, Forging, Hot cooperating, Melting, Annealing for stainless steel goods.

Character

– Installation and operation are simple and convenient, can easily to learn.

– Small size, light weight, removable, covers an area is less than 1 square meter.

– Smelting capacity of 24 hours continuously.

– Energy saving.

– Convenient to change different weight, different materials, different furnace fitness to meet the requirements of a variety of melting.

– Use the volume medium frequency induction heating power supply and different from the traditional power supply.

What We Do

Frequently Asked Questions

We are the manufacturer and we have more than 15 years experience in laser cutting & engraving equipment. Our service after sales is good, we know how to solve the problems encountered in the use of the machine.