Type of induction heating machine

OVERVIEW

Induction heating machines used electromagnetic fields to heat materials professionally and uniformly. A specialized induction heating machine for a beginning line is designed to streamline production processes by offering quick setup times, precise temperature control, and energy efficiency. TYPE OF INDUCTION HEATING MACHINE Key features include:

WE DEAL IN INDUCION HEATING MACHINE, ANNEALING MACHINE, BRAZING MACHINE, FORGING HEATING MACHINE, AND ALL TYPES OF HEAT TREATMENT MACHINES.

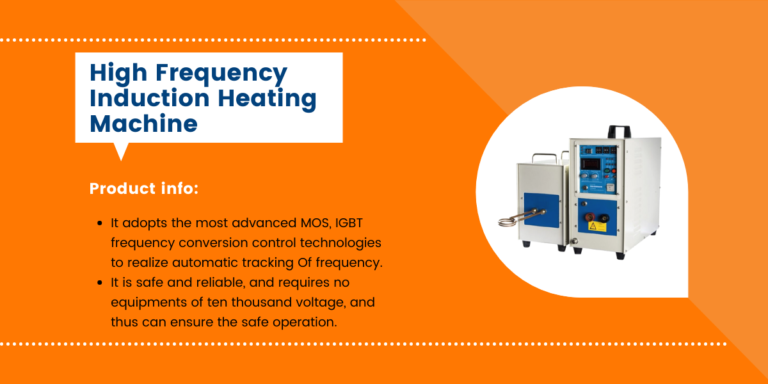

Main Features

1. It adopts the most advanced MOS, IGBT frequency conversion control technologies to realize automatic tracking Of frequency.2. It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

3. About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide higher reliability and durability.

4. It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

5. It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

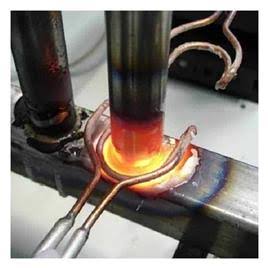

ULTRA HIGH-FREQUENCY INDUCTION HEATING MACHINE

(UHF) A Heating Device are mostly used for processes like metal hardening, brazing, soldering, Forging, melting, and heat treatment, where precise, limited to a small area heating is required.

1. Ultra high frequency heating machine series: high frequency , able to heat$O.1mm workpiece.

2.

Small size, light weight, low failure rate and conservation of energy (which can save the power by 70% as compared with glass—ceramic vacuum tube high frequency heating machines).

3.

It can ensure the solid welding point which is pleasing and delicate in appearance, integral geometric configuration, perfect surface grain, complete crystal structure of internal metal part, limited annealing range and elimination of obvious weld knot.

4.

About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide

higher reliability and durability.

4. It is applied to the welding of couplers and inserts used in metal glass manufacturing as well as electric appliance and electronics industries, non-contact brazing of internal parts of small-size relays, High-pressure refrigerating parts, headwear decorations, metal ornamental articles and art wares.

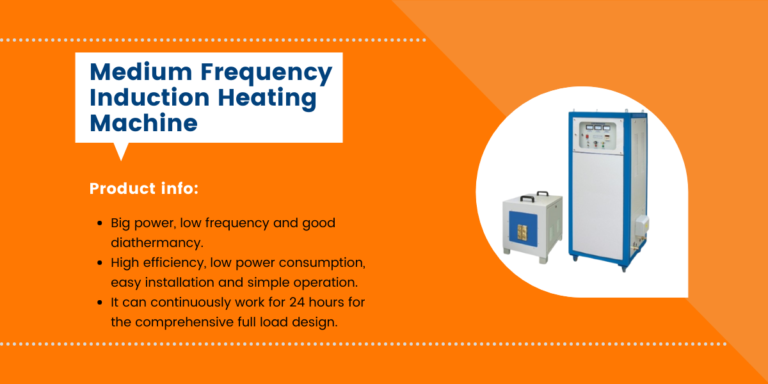

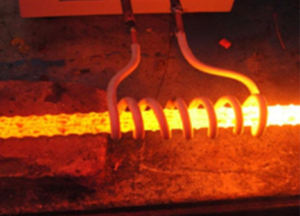

MEDIUM FREQUENCY INDUCTION HEATING MACHINE

A Medium frequency induction heating machines is a specialized device used for heating materials, typically metal, through electromagnetic induction

Main Feature

1. Big power, low frequency and good diathermancy.2. High efficiency, low power consumption, easy installation and simple operation.

3. It can continuously work for 24 hours for the comprehensive full load design.

4. It adopts the IGBT inverter circuit in parallel connection, which has high load adaptabillity.

5. It has function as over-voltae, over-current, over–heat, phase loss and water shortage alarm indications as automatic control and protection.

6. Compared with other heating modes, it can significantly promise the economic benefits, improve the quality of heated work pieces, save the energy and material, alleviate labor intensity and improve the production environment.

Super Audio Frequency Induction Heating Machine

A super Audio frequency induction heating machine (SAFIH)is a specialized devices used for heating materials, typically metals, using electromagentic induction at super audio frequencies (often around 10KHZ to 50KHZ).

Main Feature

1. This equipment adopts the IGBT inverter circuit in paralles connection, which has is high load adaptability.2. The comprehensive full load design is available for 24-hour continuous operation.

3. The digital phase locked realizes following frequency automatically.

4. Design in modules. It is installed facility and use conveniently without debugging.

5. The perfect protection function, insuring the reliability and easily maintaining of the equipments.

6. The technique of converting frequency by resonane promise efficiency of whole equipment by over 95%.

7. Economy and environment protection, It can replace of the gas/coal/electronic tube induction heating machine.

Who Are We ?

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and Induction brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms..