U Bolt Making

Rod Heating for U Bolt Making is used in fastener industrial applications, particularly in assembly and disassembly processes. They can help with things like heat on top bolts, softening them if they are damaged, or using them during installation to ensure a good fit. Disposable heating is one of the most effective ways to heat a U Bolt making, induction heating machine provides controlled and localized heat with a minimal effect on surrounding materials. Here, an evaluation is given of how this is done on a daily basis. Malhotra Technologies produces and sells solid Induction Heating Machine.

U Bolt Making

For U Bolt Making, using an induction heating machine is a powerful solution for achieving rapid and controlled heating. Here’s an outline of how a typical induction heating machine is used for heating U Bolts, and what you might look for if considering equipment from a company like Malhotra Technologies:.

U Bolt Making machine

The use of an induction heating machine in the U-bolt manufacturing process is primarily involved in the heating , phase, particularly. When producing U-bolt from thicker or high-strength materials. induction heating helps ensure efficient uniform heating for the bendind process, reducing the risk of material defects and improving precision. Here’s how the induction heating machine features:

Feature Of Induction Heating Machine

1. Main Features: The Fastest rate of heating is less than 1 second, and the rate of heating is available for adjustment and ontrol.

2. Widely applicable: it can be used to heat various meta parts(can replace the removable induction coil for different shape).

3. Low power consumption: as compared with traditional vacuum tube high frequency machine , the heat efficiency can be over 96%.

4. High Effectiveness: it is applicable to control the temperature for heating work pieces that it has such features as uniform heating, fast hot and limited oxic horizon.

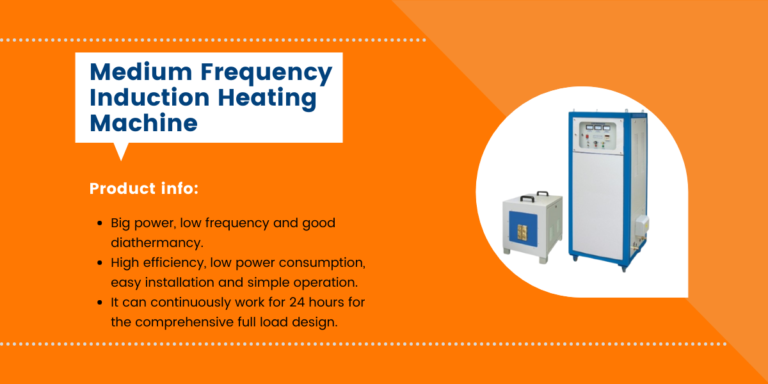

5. High Efficiency: It can work continuously for 24 hours for comprehensive full load design. And with the function of automatic setup, just one person can operate it that can save the process.

6. Easy operation: it has a weight of only several dozens of KGS and with small size that can save the space of the workshop and can be moved conveniently.

U-bolt making process advantage of New Induction Heating machine.

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufacturer and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machine,Induction Forging Machine, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 kw series induction heaters, 25 kw series induction heaters, 35 kw series induction heaters, 70 kw series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials secured from retailers following international model.Special Purpose KNOW MORE.

U BOLT HEATING by Induction Heating Machine

Super Audio Induction Heating Machine

Super audio frequency induction heating machines (10-100 kHz) provide controlled, medium-depth heating that are ideal for applications such as surface hardening, brazing and shrink fitting, commonly used in the automotive and aerospace industries. Are going.

Ultra High Frequency Induction Heating Machine

Ultra-high frequency induction heating machines provide precise, fast heating for delicate applications such as surface hardening, micro-welding and soldering in electronics and medical device manufacturing. They excel in controlled, targeted heating with minimal thermal distortion.

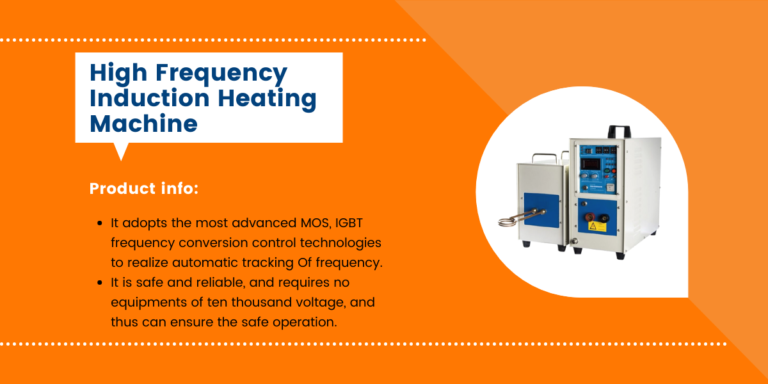

high frequency induction heating machine

A high-frequency induction heating machine is a specialized device that uses electromagnetic induction to heat materials, typically metals, for various industrial processes like hardening, brazing, welding, and annealing.

INDUCTION BRAZING MACHINE

brazing is a fusion and solidfication process which is used in soldering industries that two object surface add by brazing powder and this methof called brazing.

induction hardening machine

An Induction Hardening Machine is an electric machine that produces induction heating. Hardening is a Heat Treatment method used to treat a specific area of a metal workpiece.

Induction Annealing Machine

An induction annealing machine is a part of industrial equipment designed for annealing Heat method, that is heat treatment system used to modify the properties of materials (typically metals)