Induction Brazing furnace

Brazing is a heat treatment method with Induction Heating Machine. Induction Heating means to produce the alternating magnetic field through induction coil after induction heating equipment outputs high-frequency current to make the workpiece heated quickly.

Malhotra Technologies is always ready with the solution of induction brazing machine. These come with induction heater, coil, brazing material, flux, fixtures, cooling and temperature control.

These induction brazing machines have increased the industrial work due to their good features.

These are automatic and manual also.

Induction Brazing Process

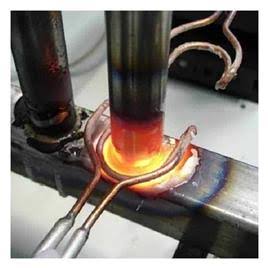

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of solder, or the temperature of metal material to reach between non-metallic material. Its main features: good working, conditions, high efficiency, good tightness and performance after brazing, simple operation and high safety, no pollution, and high, fire resistance.

Applications

Such as: cutting tools

(turning tool, milling cutter, woodworking tools, serrated blade, shoe materials, diamond tool, deep hole drilling, drilling, etc.)

faucets, bathroom, accessories, showers, coal drill, drill bit, terminal blocks, furniture fittings. refrigeration equipment, pad tube, heating plate, egg beater, lighting accessories, such as branch distributor, bicycle up and down the fork iron, copper pieces, aluminium, stainless steel brazing.

2) Do not add solder connection.

Such as: computer radiator core and copper core, motor rotor and shaft, horn net preparations, hanger hook, copier carbon brush melt, aluminium-plastic pipe, the compound preparations kettle, tool shank cure, tableware curing rubber handle, battery pole ear forming, aluminium foil sealing, etc.

Induction Brazing Vs Other Heating Techniques

Induction Brazing Specification

1. Heating Speed = <1 Second (Super Fast)2. Energy Saving = 90%-95%

3. Safety and Environment = Noise-Free, Pollution-free

4. Automation= Easy and Single Operator Handling

Traditional Methods (flame, torch, vacuum tube HF)

1. Heating Speed = Time and Skill Intensive2. Energy Saving = less Efficiency, Higher Wastage

3. Safety and Environment = Smoke, Fumes, Fire risk

4. Automation= Manual efforts, Skilled labor requirement

Benefits of Induction Brazing furnace

1) Fast Heating: the quickest rate of heating is less than 1 second, and the rate of heating is available for adjustment and control.

2) Low power consumption: as compared with traditional vacuum tube high frequency machine , the heat efficiency can be over 95%.

3) Widely applicable: It can be used to heat various metal parts (can replace the removable induction coil for different shape).

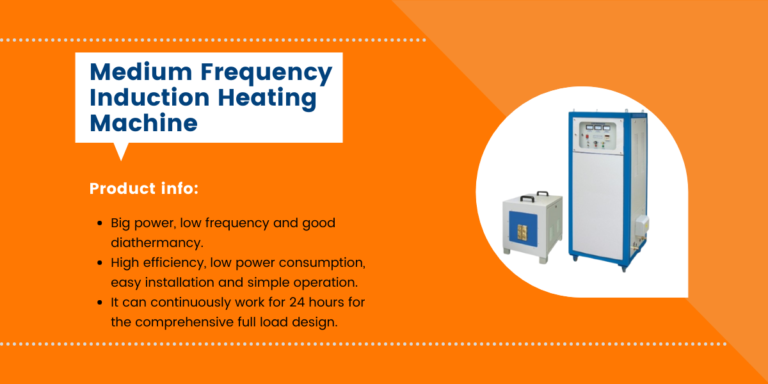

4) High Efficiency: It can work continuously for 24 hours for comprehensive full load design. And with the function of automatic setup, just one person can operate it that can save the process.

5) Environmental Protection: it is free of any noise, exhaust gas and dust that can provide a much better environment for the workers than the conventional heating with such fuels as coal, gases, and oil.

Portable Induction Brazing Machine and Handheld Induction Heating Machine

Handheld Brazing Machine or Portable Induction Brazing Machine is a Industrial Induction Heating machines. 1m,2m,3m,5, amd 20m flexible cable with Induction Brazing machine for Copper pipe brazing, steel to copper brazing, ss steel brazing, and ac pipeline brazing. Flexible Induction Brazing Machine with Digital Technology is best

Why Choose Malhotra Technologies ?

With Over (20) Years or expertise in industrial heating system, Malhotra Technologies is Trusted by Leading Manufacturers to

Provide High Performance,

Reliable and

Cost Effective Heat Treatment Solutions. Our Commitment to in house research and Development and Innovation ensures that each machine meets the Highest Industry Standards of Quality, Safety and efficiency.

> EXAMPLE OF BRAZING <

Induction Heating Equipment (induction Heating machine)

Induction Heating machine is using electromagnetic current to generate heat directly within conductive materials, without direct contact or flame. This type or heating is perfectly, precise and clean, making it ideal for a range of industrial and manufacturing applications. Induction Heating Machine industrial requirement. Malhotra Technologies is a reputed company.

Who Are We?

Malhotra Technologies was founded in 2006, which is engaged in R&D, production and sale of solid Induction heating machine professionally. Several senior experts of induction heating equipment gathered here, who initiate the induction heating machines with environmental protection and highly effective energy conservation, positively and diligently.

Now there are series of products range from 3KW to 300KW, including the ultra-high/ super-audio/ medium frequency induction heater, IGBT energy saving IF power supply and special equipment (e.g. High-frequency quenching machine, Medium-frequency induction melting furnace, super audio-frequency annealing machine, Induction forging furnace, Brazing machine, Branch Distributor/Bicycle fittings special-purpose welding machine, Railway river furnace, etc). These products are widely applied in the heating of hardware, metal (steel, iron, copper, aluminum) processing, plastic, deeply heating shaping, brazing, hardening, melting, annealing, hot cooperation and so on.

Induction Brazing Machine Manufacturer in India. leading the way in precision and efficiency

India’s manufacturing sector is developing rapidly, and induction brazing machine plays an important role in shaping the industrial future. From automotive to aerospace, induction brazing machine is becoming essential for all industries. Precision, speed and high-quality bonds are demanded.

As India’s industrial base is expanding, finding the right induction brazing machine manufacturer is a must for companies that want to stay ahead in the competition. Naveen Malhotra discusses his company’s services. Why is India becoming a leader in the induction brazing market, why do we make these months an integral part of manufacturing, and how to choose the best manufacturer for our business needs?

Malhotra Technologies has played a role in the growth of the industry for the last 15 years

FREQUENTLY ASKED QUESTIONS

Induction Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of solder, or the temperature of metal material to reach between nonmetallic material. Its main features: good working conditions, high efficiency, good tightness and performance after brazing, simple operation and high safety, no pollution, and high fire resistance.

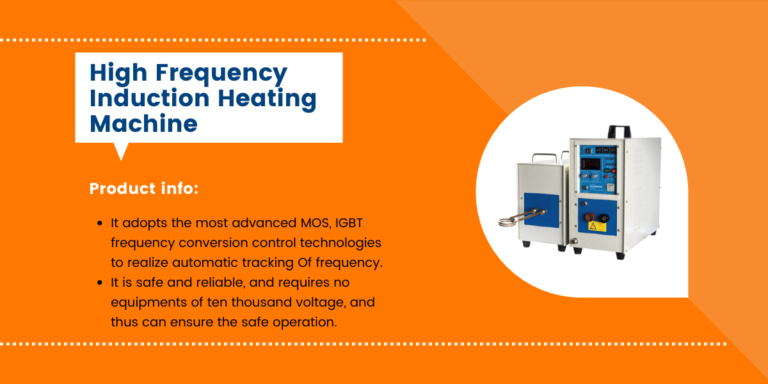

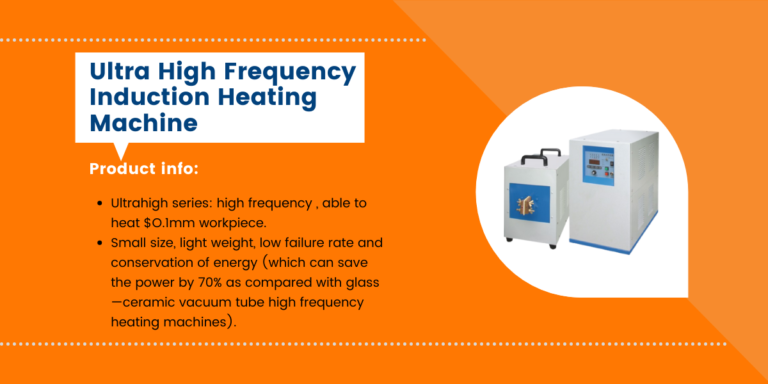

In Today’s Modest Manufacturing Environment, The Induction Brazing process needs to be Fast, Environmentally , Friendly, and Precise — and this is why Induction Brazing Machine has Beat all Traditional Techniques. High Frequency Induction Heating Machine and Ultra High Frequency Induction Heating Machine Developed by Malhotra Technologies are redefining Manufacturing in India with care and energy-saving heating.

Induction Brazing Machine in Bahadurgarh (Haryana).